We’re pleased to announce that we are exhibiting at this years’ Offshore Energy Conference and Exhibition in Amsterdam, the Netherlands. It’s the first time that Stewart-Buchanan Gauges has had a presence at the event and our exhibition team will be Sales Director, John O’Donnell, Export Manager, Russell Robinson and Marketing Manager, Robert Baird.

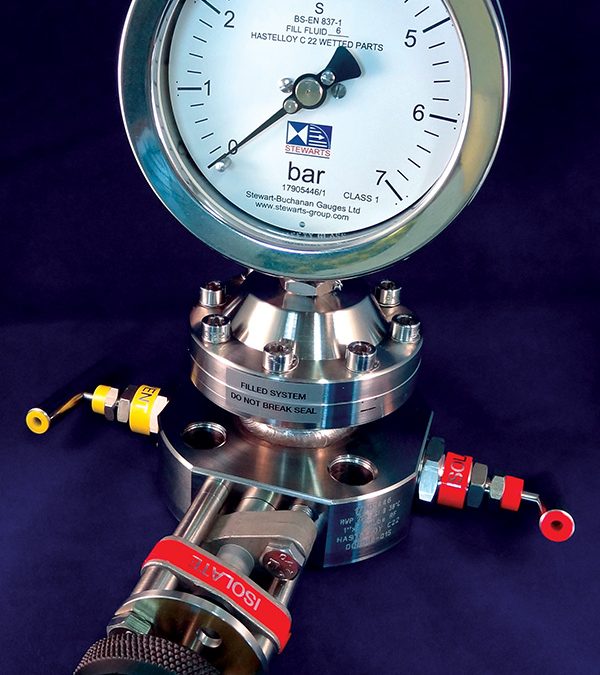

The two-day event takes place from 10-11 October 2017 and includes a conference addressing the technical, operational and commercial challenges associated with future growth in the offshore energy sector. Organisers are expecting up to 12,000 visitors to attend over the course of the two days. While one of our core markets, the oil and gas sector, features strongly, the exhibition and conference also covers offshore wind and marine energy. The offshore renewable energy sector is one that we have worked with recently and we’re keen to increase our presence in this growing market. We will be showcasing our relevant gauge and valve products on our stand.

If you’re planning to attend, please come and say hello! Our stand number is 1.095, conveniently located near the bar area in Hall 1 and you can find it on the exhibition map here. You can also find out more about the event on the Offshore Energy 2017 website.

Or, if you are attending the event and would like to book some time with a member of our team, please get in touch.