COMPENSATED SUBSEA PRESSURE GAUGES

The STEWARTS range of compensated subsea pressure gauges have a 100% filled case that has a special compensation device, allowing the internals of the case to be pressurized equal to the external ambient pressure as the gauge is submerged to depth.

The benefit of this method is that as the internal and external pressure remain in balance, there is no need for a pressure proof case, allowing our 8000 series compensated gauges to work at your deepest depth applications.

A conventional (zero ref = 1 atm) subsea gauge will compare the subsea reading to atmospheric or gauge pressure at the surface (i.e. the zero point equals 1 atmosphere or approximately 1 bar absolute). However, the compensated gauge will compare the subsea reading with the local ambient pressure at depth with the zero point being equal to the ambient pressure.

Provided the system being measured is also affected by this increase in ambient pressure then the gauge reading will be correct. However, if the system pressure is not affected by the increase in ambient pressure, the gauge will start to read increasingly low as the depth increases.

- We offer two types of compensation. Our unique welded stainless steel diaphragm (for durability) (8022/8024) & the conventional Nitrile rubber diaphragm (8032/8034)

- Robust 316 Stainless Steel Case/ Bezel / Flange / Socket & Element, (Bead blasted non reflective bezel and flange) removable bezel design allows repair or recalibration

- The socket is welded into the case providing a strong permanent seal

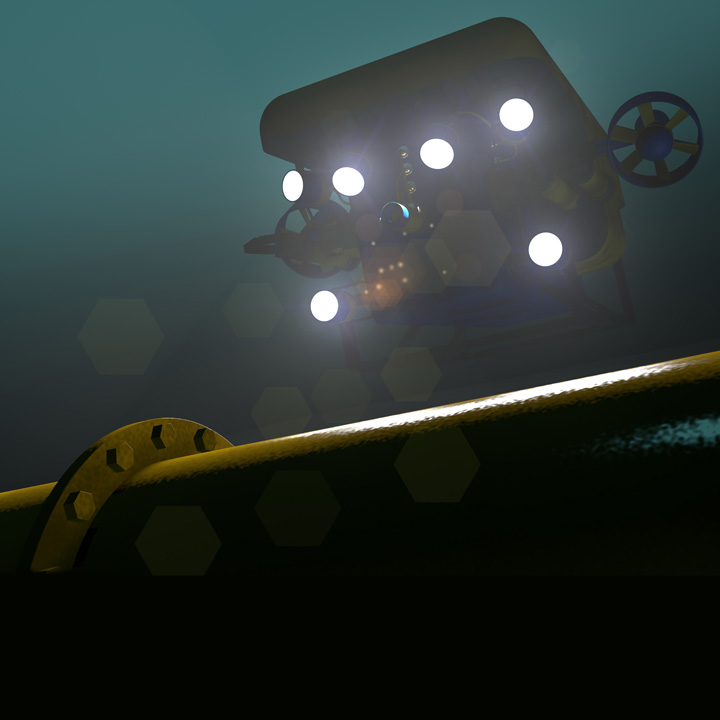

- STEWARTS has also developed a exclusive Aegis-Guard (Acrylic) which will offer protection to the gauge in the event of external contact. This will aid in protection against subsea construction and remediation applications when using subsea tooling or ROV’s. The cover can be replaced manually if damaged, mitigating the need to replace an entire gauge.